HISTORICAL USE OF MGO BAORD

►Magnesia is widely used primarily as wallboard alternative to conventional gypsum-based drywall and ply-woods. The magnesia boards can be scored and snapped, sawed, drilled, and fastened to wood or steel framing. Magnesia boards are a good example of the advances made in construction materials to meet changes in building models for safety and durability.

►Magnesia cement uses in masonry construction is ancient. It was used primarily as a mortar component and stabilizer for soil bricks. Magnesia has also been identified in the Great Wall of China and other ancient landmarks. Roman cement is reported to have contained high levels of magnesia. In West, Portland cement replaced magnesia for masonry uses in the 20th century when energy was cheap and mold infection was poorly understood. However, some projects continued to use magnesia.

►Due to its fire resistance and safety ratings, New York and New Jersey were early adopters of magnesia cement board. Florida has adopted magnesia boards for mold/mildew resistance. It is hurricane and impact tested and approved in Miami-Dade County. Located in Taipei, Taiwan, magnesia board can be found on each stories of Taipei 101 Building. Magnesia board was used on the inside and outside of all the walls, fireproofing beams and as the sub-floor sheathing.

WHAT ARE MGO BOARDS

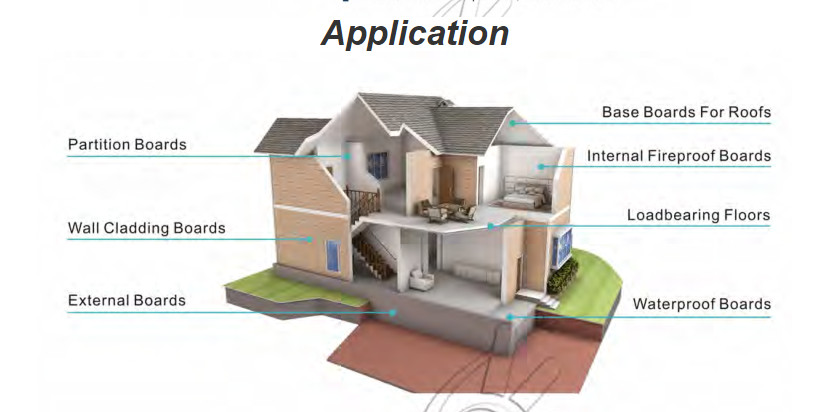

►MGO Boards are multipurpose dry construction material used for interior as well as exterior purposes, as cladding, partition, ceilings, flooring, fire protection, water Proofing, roof Construction, heat insulation, and acoustic insulation. MGO boards can be used for fireproof purpose—installing fire-resistant MGO boards will make sure that if a fire occurs, it doesn’t spread around your house and the boards don’t collapse, posing a major hazard for you and your family.

HOW MGO BOARDS ARE MADE

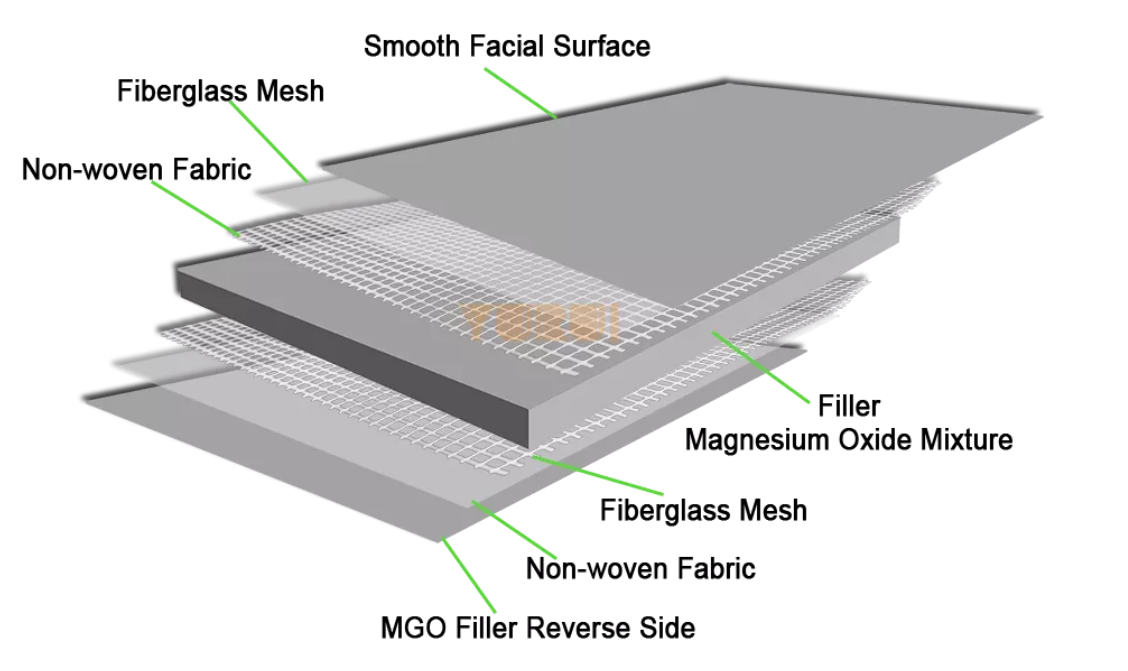

►In a process similar to creating Portland cement, MGO powder is combined with other ingredients and water to form a cement slurry. This slurry is then embedded with layers of glass fiber mesh, formed and allowed to cure. Once fully cured, the hardened good quality magnesium oxide cement boards are made.

►For builders, structural stability and fire-resistant qualities make MGO board an excellent choice as sheathing or sub-floor in many wood-framed house and light commercial buildings. MGO boards offer multifamily builders a time-saving, high-performance material for use in fire-resistant and sound-rated assemblies.

►We offer two different types of MGO boards and use them as base boards to make decorative boards. One is MGO board with Chloride: magnesium oxide, magnesium chloride (MgCl2), wood fiber, fiberglass mesh and additives. Another is Sulphate MGO Board: magnesium oxide, magnesium sulphate (MgSO4), wood fiber, fiberglass mesh and additives. The magnesium chloride is easy to absorb the moisture from ambient and lead to quality issues. Now the sulphate MGO board is becoming the first choice for most customers, like in the USA, Canada, Europe, Australia and so on. Additionally, the board can be made into decorative wall boards with different types of layer on the surface of board.

MAIN COMPONENTS OF MGO BOARDS

►Magnesium oxide

Magnesium oxide is a vital component of a MGO panel. Magnesium is a solid at ambient temperature and, like aluminum, is lightweight in its purest form. This chemical stabilizes and becomes non-flammable when coupled with oxygen, making it perfect for home construction and furnace lining.

►Additives (Magnesium cement/Wood flour)

Wood flour, magnesium cement, and other additives, in addition to the base materials used in the making of MGO panels, are added to the mixture, depending on the grade of MGO boards being produced. Because MGO panels come in a variety of textures, thicknesses, and quality, the additions in each type vary slightly.

►Fibers (Fine screed, Fiberglass mesh)

For further strength, durability, and flexibility,MGO panels are reinforced with some form of fiber. To reinforce the boards, fine screed, glass mesh, or other fibers are frequently employed, either within the board or on its surface.

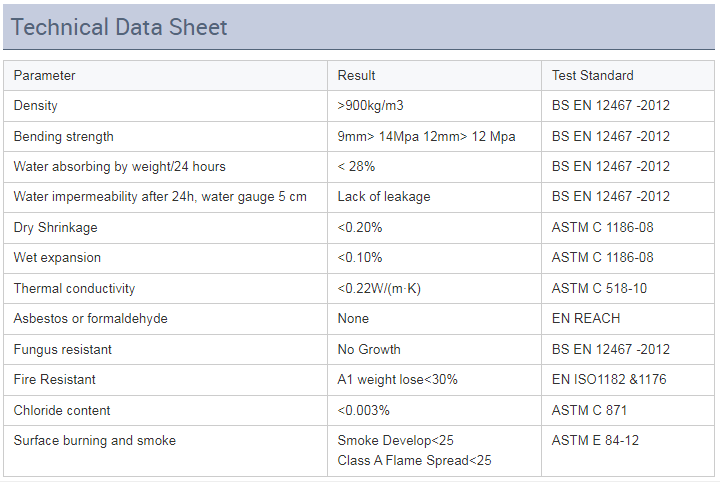

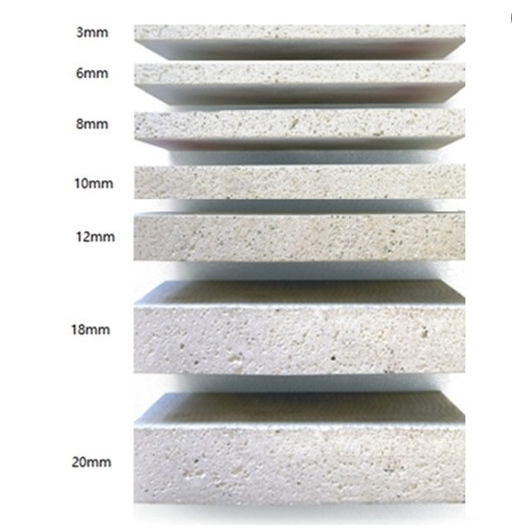

SPECIFICATIONS

Standard size:1220x2440,1220x2740,1220x3050mm

Standard thickness: 3 to 20 mm

Density:0.8-1.3g/cm³

Color: normal color is white, also could make green, gray, brown

Edge: Square, tapered, shiplap, T&G

Backside: Rough or sanded

CHARACTERISTICS

►Fire resistance

Magnesium oxide boards are essentially non combustible, with a flame spread of zero and a smoke development of zero. These properties make it highly effective either standing alone as a sheathing or under-layer when laminated to other materials.

►Easy to install

MGO panel can be used in many applications, both interior and exterior, on wood frame, metal frame and SIP assemblies.

►Water resistance

Magnesium oxide inherently has very low water absorption and any moisture is naturally expelled. There is also no deterioration from freeze/thaw cycles.

►Mold resistance

Since MGO board will not hold moisture to support mold growth. Nothing within the product as a food source for insects.

►Versatility

Whether used on its own as a sheathing, wallboard or in conjunction with other building materials such as plywood, OSB or drywall, it can add tremendous value.

►Impact resistance

Magnesium oxide board has excellent tensile properties.

Contact: Peter Wang

Phone: +86-17355223662

Tel: +86-17355223662

Email: peterwang@fireproofshelter.com

Add: No.3333 Huaishang Blvd, Bengbu, Anhui Province, China

We chat